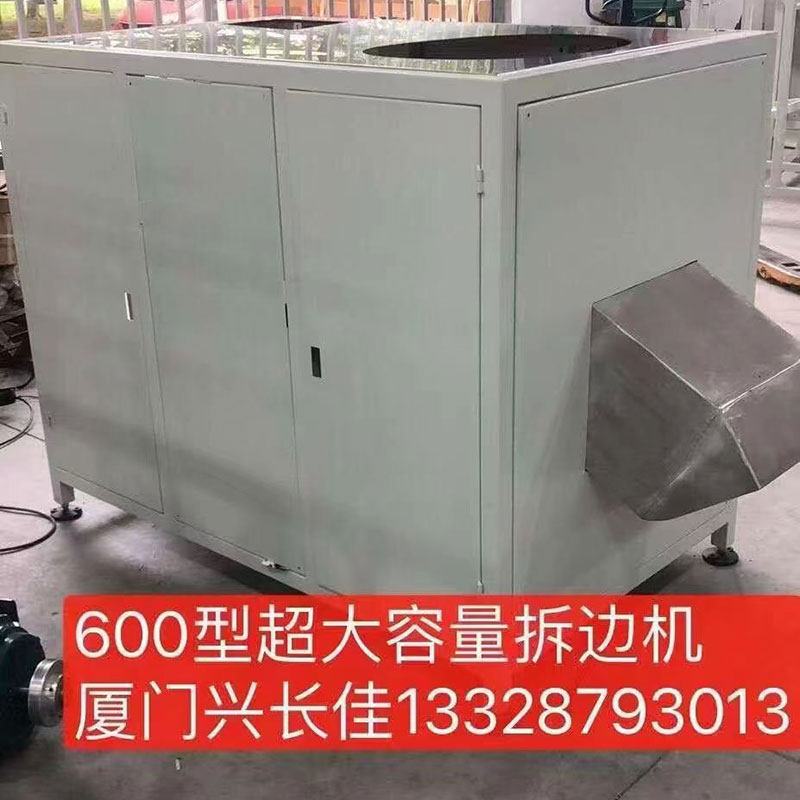

Rubber deflashing machine(Super Model) XCJ-G600

product description

The super model rubber deflashing machine with a 600mm diameter is a state-of-the-art piece of equipment designed specifically for the efficient removal of flash from rubber products, such as O-rings. Flash, which refers to the excess material that protrudes from the molded rubber part during the manufacturing process, can affect the functionality and appearance of the final product. This machine is specially designed to trim the flash quickly and accurately, ensuring that the O-rings meet the required specifications.

One of the standout features of this machine is its high efficiency. With a trimming time of only 20-40 seconds per O-ring, the machine can swiftly process a considerable amount of rubber products. In fact, it is so efficient that one machine can handle the workload that previously required three machines. This not only saves space and resources but also significantly improves productivity and reduces production costs.

The machine's technical parameters contribute to its impressive performance. The barrel depth of 600mm and diameter of 600mm provide ample space to accommodate a substantial number of O-rings, allowing for efficient batch processing. The powerful 7.5kw motor and inverter further enhance its performance, ensuring smooth and reliable operation. Additionally, the compact dimensions of 1750mm (L) x 1000mm (W) x 1000mm (H) and net weight of 650kg make it suitable for installation in various manufacturing environments.

The operation of this rubber deflashing machine is relatively straightforward. First, a batch of O-rings, weighing approximately 15kg, is loaded into the machine. The machine then automatically trims the flash from each O-ring, ensuring consistent and precise cuts. The trimmed flash is efficiently removed, leaving behind clean and flawless O-rings. With its automatic feeding and discharge mechanisms, the machine can continuously process batches of O-rings with minimal manual intervention.

This machine offers several advantages over traditional manual deflashing methods. Manual deflashing is labor-intensive and time-consuming, requiring skilled operators to meticulously remove the flash from each O-ring. In contrast, this machine guarantees consistent and accurate trimming with minimal operator involvement. This not only saves time but also reduces the chances of human error, resulting in higher-quality and more uniform finished products.

In summary, the super model rubber deflashing machine is a highly efficient and effective solution for removing flash from rubber products, specifically O-rings. Its fast trimming time, high productivity, and compact design make it a valuable asset for manufacturers seeking to streamline their production processes. By investing in this machine, businesses can significantly improve their operational efficiency, reduce production costs, and deliver superior-quality rubber products to their customers.